Zeron® 100, 25Cr Super Duplex Stainless Steel

Zeron 100 contains 25% chromium and 7% nickel and 3.6% molybdenum along with copper and tungsten additions. Zeron 100 has a 50–50 austenitic–ferritic structure. It also has greater resistance to chloride pitting, crevice corrosion and stress corrosion cracking than exhibited by the standard 300 series stainless steels.

Zeron 100 is super duplex stainless steel often recognised as UNS S32760. Zeron 100 has modified mechanical properties as compared to grounded S32760. Zeron 100 has induced impact and tensile test requirements as mentioned below. Zeron 100 is not recommended for uses which involve extended exposure to temperatures greater than 572°F (300°C) as this causes a substantial reduction in toughness. Zeron 100 is highly resistant to corrosion in a wide range of organic and inorganic acids. The copper content gives excellent resistance to corrosion in many oxidising acids. This alloy is also highly resistant to strong alkalis.

At TorqBolt we stock a huge variety of Studs, Heavy Hex Nuts, washers and headed bolts along with their corresponding forgings, pipe fittings, flanges, pipes, plates, sheets and bar stock, wire, wirelines, welding wire and covered electrodes.

| UNS |

S32760 |

| WerkStoff |

1.4501 |

| Steel Number |

X2CrNiMoCuWN25.7.4 |

| SAF |

2507 |

| Plates And Sheets |

ASTM A240 ; BS EN 10028-7 / 10088-2 |

| Forged Flanges, Fittings, Rings,Forged Pipes |

ASTM A182 F55 |

| Bars and Shapes |

ASTM A276 /A479 ; BS EN 10088-3 / BS EN 10273 |

| Fasteners, Stud Bolts and Heavy Hex Nuts |

ASTM A1082 / ISO 3506-1 D8 |

| HIP Flanges and Fittings |

ASTM A988 |

| Forgings |

ASTM A473 / A314 |

| Pipes, Tubes and Tubings |

ASTM A789 / A790 / A928 |

| Pipe Fittings |

ASTM A815 |

| Castings |

ASTM A890 / A315 / A995 |

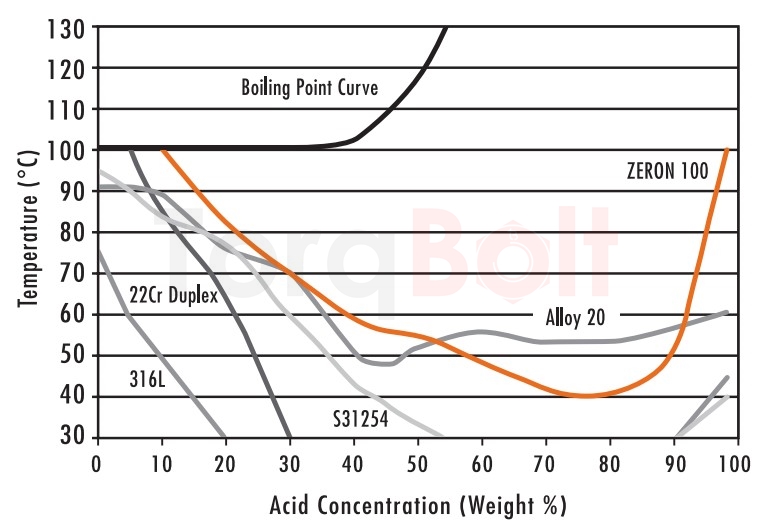

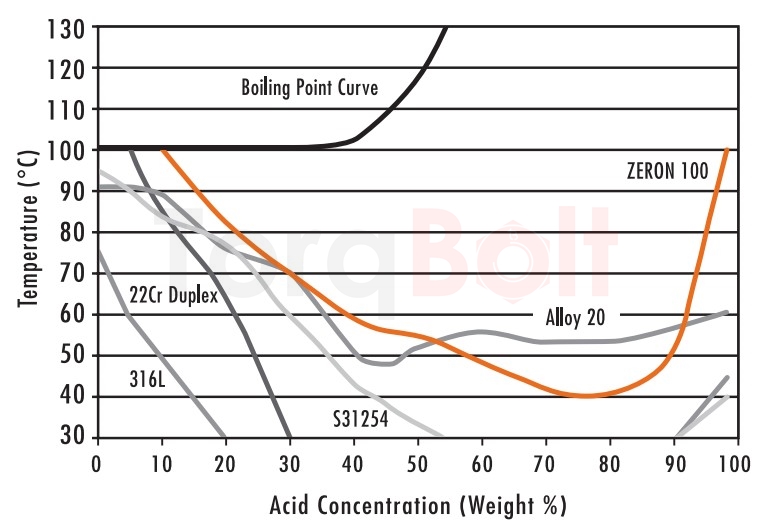

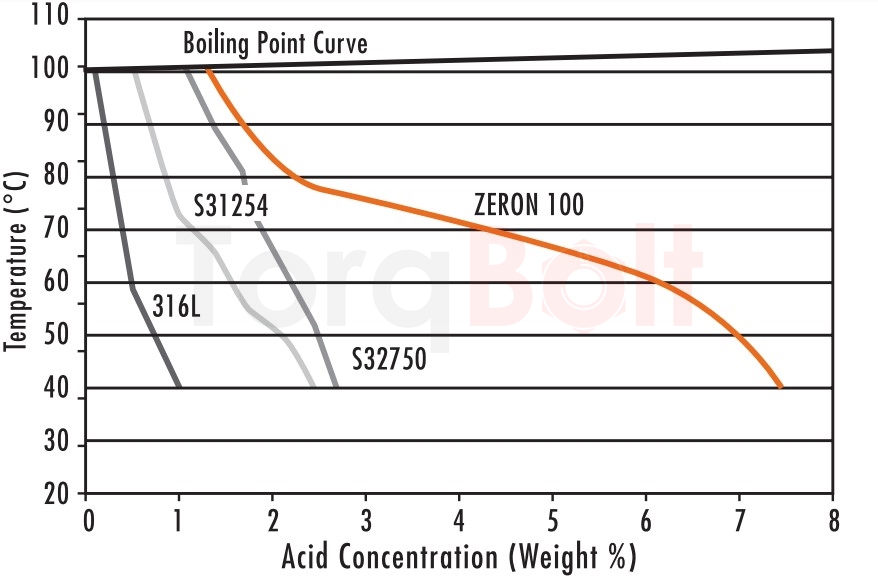

Zeron 100 is highly resistant to corrosion in a wide range of organic and inorganic acids. The copper content gives excellent resistance to corrosion in many oxidising acids. Commercial acid applications often contain chlorides and other impurities which can cause corrosion of some stainless steels. Zeron 100 offers much improved corrosion performance in these environments.

Figure 2 : Iso-corrosion curves 0.004 ipy (0.1mm/y)

for some stainless steels in Sulfuric Acid

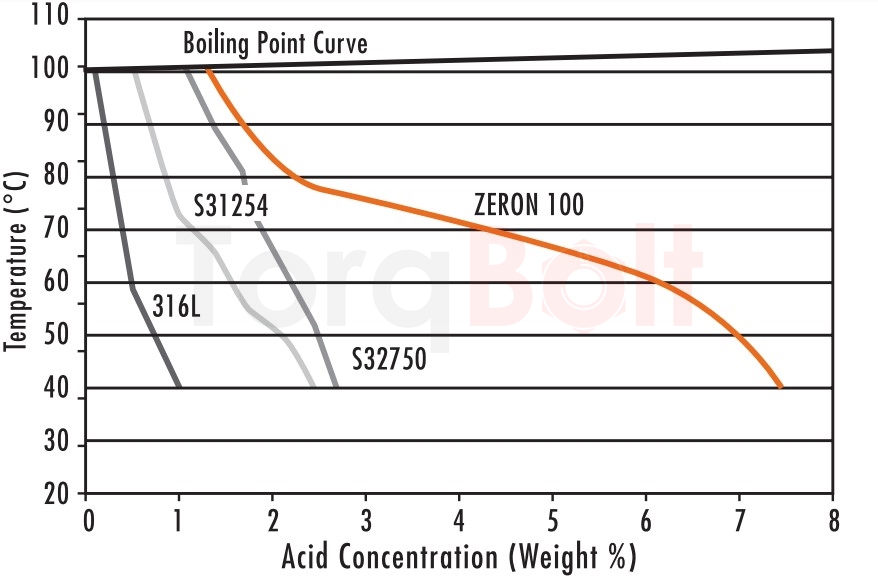

Figure 3 : Iso-corrosion curves 0.004 ipy (0.1mm/y)

for some stainless steels in Hydrochloric Acid

Zeron 100 is also highly resistant to strong alkalis. The production of caustic soda results in hot, strong solutions and even in 60 wt% caustic soda, Zeron 100 has very low corrosion rates (<0.004 ipy). Caustic soda is often found with chlorides in extraction processes and even with 10g/L chloride, Zeron 100 has excellent corrosion resistance. Three years service experience of fabricated Zeron 100 pipework in 2M caustic soda with chlorides at 446°F (230°C) has been excellent.

Exposure to 6% FeCl3 for 24 hours in accordance with ASTM G48 method A to determine the maximum temperature at which no pitting occurs (the critical pitting temperature, CPT), has given the following results:

Solution annealed wrought and cast Zeron 100: 158 - 176°F (70-80°C) depending on product form and manufacturing route.

Zeron 100 welded with Zeron 100X filler metal: 95-140°F (35 - 60°C), depending on the welding variables, i.e. process, joint geometry, procedure etc.

These values are for single exposure testing; testing a single specimen at a series of increasing temperatures gives a higher CPT value.

The resistance to localized corrosion is often assessed by use of the PREN number (%Cr + 3.3 x %Mo + 16 x %N). Zeron 100 is made to a minimum PREN of 40, ensuring a guaranteed and high resistance to pitting and crevice corrosion. Zeron 100 has been in service in seawater since 1986 as castings, and since 1989 as wrought pipes and fittings giving satisfactory performance.

At sea water temperatures above ambient, 68°F (20°C), the risk of crevice corrosion increases. Zeron 100 resists crevice corrosion up to 131°F (55°C) but is limited by the pitting resistance of the welds to about 104°F (40°C). With the application of post weld surface treatments, seawater temperatures up to 149°F (65°C) have been handled successfully.

Short term elevated temperatures upsets are not uncommon in cooling water circuits. Laboratory tests and field experience have shown that Zeron 100 does not suffer crevice corrosion easily during short upsets and, when corrosion does initiate, repassivation occurs readily on cooling, and at temperatures higher than the normal operating temperature of 104°F (40°C). Super austenitic steels and super duplex steels that do not contain copper and tungsten have lower repassivation temperatures than normal operating temperatures, so any corrosion that is initiated during the upset will continue to propagate when the system reaches normal operating conditions once more.

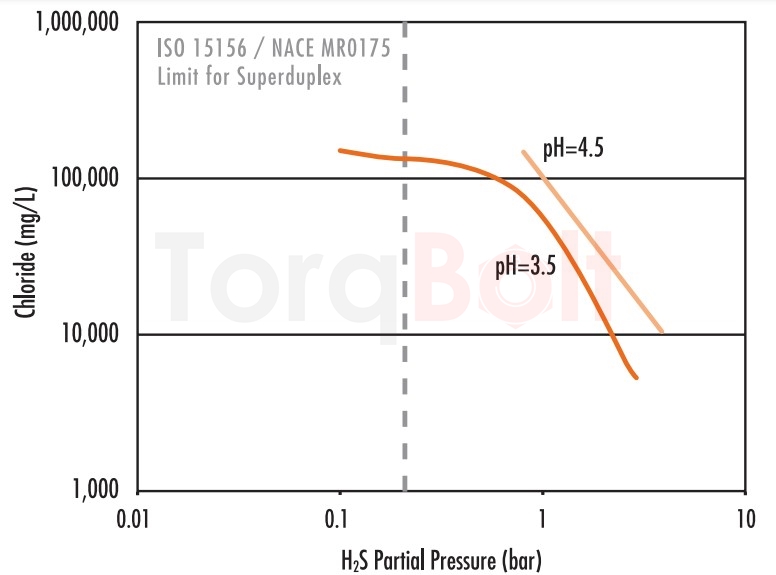

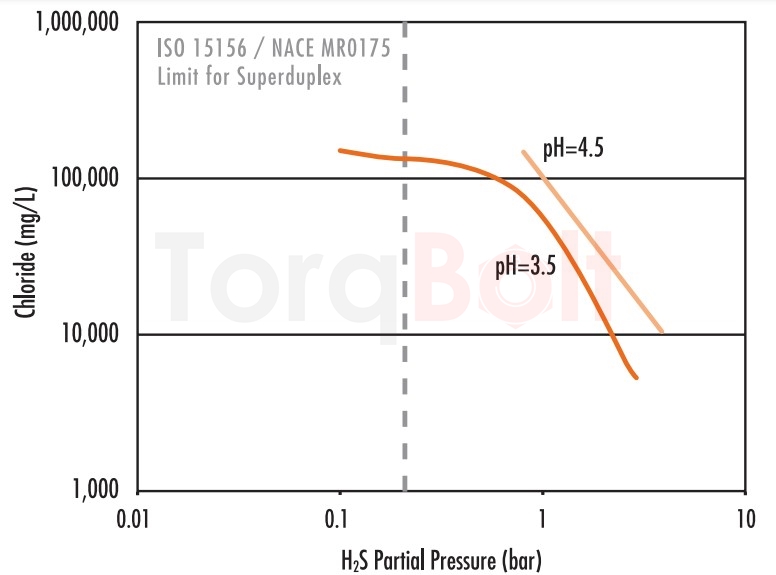

Zeron 100 has excellent resistance to stress corrosion cracking (SCC) in both chloride environments, and process environments containing H2S and CO2. Zeron 100 is listed in ISO 15156 / NACE MR0175 part 3 as being suitable in sour service at 0.2 bar partial pressure of H2S. In brines with lower chloride contents Zeron 100 can tolerate much higher pressures of H2S, as shown in Figure 4. As the pH, at temperature and pressure, increases, so does the resistance to sulfide SCC (Figure 4).

Figure 4 - Limits of use for Zeron 100 in brines containing H2S

In common with all high strength steels, duplex and super duplex stainless steels can be susceptible to hydrogen embrittlement if stressed above the specified minimum yield strength in the presence of hydrogen. Hydrogen embrittlement therefore becomes an area for consideration when these steels are used subsea with conventional cathodic protection. However, the proper application of normal design stress criteria and coating technology has allowed many subsea projects to utilize duplex and super duplex stainless steels successfully for a number of years.

Zeron 100 should be solution annealed in the temperature range 2012-2084°F (1100-1140°C) followed by water quenching.

Hot forming of Zeron 100 should be carried out in the temperature range 2012 - 2336°F (1100°C - 1280°C). It is recommended that this is followed by solution annealing and water quenching. Components should subsequently be pickled or fully machined.

Zeron 100 can be adequately cold formed by various processes but the high mechanical properties should be taken into account. It is recommended that any cold work in excess of 10% -15% is removed by solution annealing and water quenching.

It should be noted that cold working above these limits can result in hardness levels above those specified in standards such as ISO 15156 / NACE MR0175 for cold worked superduplex.

Where a solution anneal and quench as a post-weld heat treatment is to be carried out, Zeron 100 is usually welded with matching composition consumables (Zeron 100M). With overalloyed consumables (Zeron 100X), no post-weld heat treatment is necessary. Corrosion and mechanical properties similar to the parent metal can be obtained following recommended procedures. A separate brochure on the optimum parameters for a range of welding operations is available from our Sales Department as bulletin number 105.

Zeron 100 requires a little more care in machining than the 300 series austenitics. If heavy or uneven machining to tight tolerances is to be carried out on wrought Zeron 100 components, machining should be carried out in stages. As a last resort, a stress relieving heat treatment can be applied but this can result in a reduction of toughness and corrosion resistance.

ASTM A923 - Test Method A - Sodium Hydroxide Etch Test for Classification of Etch Structures of Duplex Stainless Steels

ASTM E562 - Standard Test Method for Determining Volume Fraction by Systematic Manual Point Count

ASTM G48 - Test Method A - Standard Test Methods for Pitting and Crevice Corrosion Resistance of Stainless Steels

ASTM A923 - Test Method C - Ferric Chloride Corrosion Test for Classification of Structures of Duplex Stainless Steels

Zeron 100 Product Range

Surface Treatments

- Xylan 1070 / 1014 / 1400 / 1424

- Xylar 2 / 101

- SermaGard 1105 / 1280

- Dacromet 320 / 500

- TakeCoat 1000 Ceramic

- Magnigard

- MolyKote

Certifications

- ISO 9001 - 2015 Certified

- PED 2014/68/EC

- NACE MR0175/ISO 15156-2

- NORSOK M-650 MDS 055

- DFAR

- MERKBLATT AD 2000 W2/W7/W10