| Trade name |

Eq. ASTM Specification |

Condition |

Tensile Strength, ksi |

0.2% Offset Yield Strength |

Elongation in 2 in., % |

Reduction of Area, % |

Hardness, Brinell (Max) |

Charpy Impact |

| Zeron 100 SA |

ASTM A276/A 479 Cond.A |

Solution Annealed |

109 |

80 |

25 |

– |

290 |

– |

| Zeron 100 SA |

ASTM A1082 |

Solution Annealed |

109 |

80 |

25 |

30 |

290 |

– |

| Zeron 100 FG |

ASTM A276 Cond.S |

Solution Annealed+Strain Hardened |

125 |

105 |

16 |

– |

335 |

– |

| Zeron 100 FG |

ASTM A193 Grade B7 |

Solution Annealed+Strain Hardened |

125 |

105 |

16 |

50 |

321 |

40 Joules (29.5 ft. lbf) minimum at -46oC (-50oF) |

| Zeron 100 FLT |

ASTM A320 Grade L7 |

Solution Annealed+Strain Hardened |

125 |

105 |

16 |

50 |

321 |

27 Joules (20 ft. lbf) minimum at -101oC (-150oF) |

| |

Wrought (UNS S32760) |

Cast (UNS J93380) |

| Yield Strength (0.2% offset) |

80 ksi (550 MPa) |

65 ksi (450 MPa) |

| Tensile Strength |

109 ksi (750 MPa) |

101 ksi (700 MPa) |

| Elongation in 50mm |

25% |

25% |

| Hardness |

28 HRC Max |

24 HRC Max |

Temp,

°C (°F) |

Yield Strength, 0.2% offset ksi

(MPa) |

Tensile Strength ksi

(MPa) |

| 68 (20) |

550 (80) 550 |

109 (750) |

| 122 (50) |

470 (68) 470 |

102 (700) |

| 212 (100) |

430 (62) 430 |

97 (670) |

| 302 (150) |

400 (58) 400 |

90 (620) |

| 392 (200) |

380 (55) 380 |

88 (610) |

| 482 (250) |

370 (54) 370 |

87 (600) |

The properties for forgings are typical values for section thicknesses up to 11.81” (300mm) solid or 9.84” (250mm) in an annulus with a minimum bore of 3.94” (100mm).

As the properties from forgings are very dependent upon the product route and the actual forging ratio, then properties and design are by agreement for other than standard items.

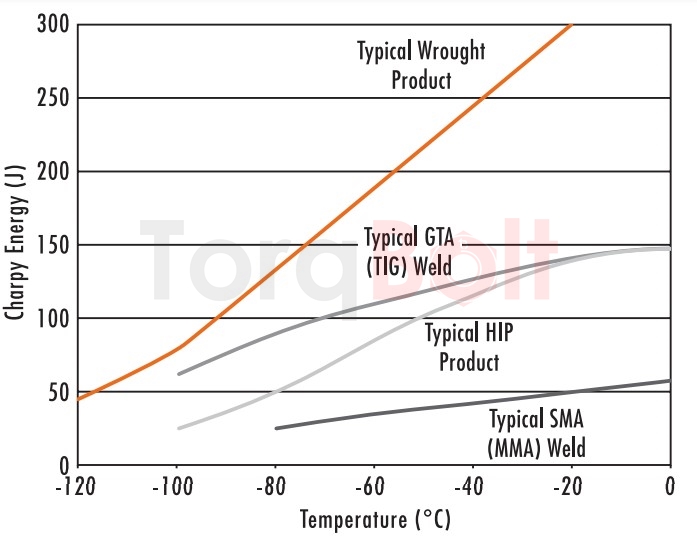

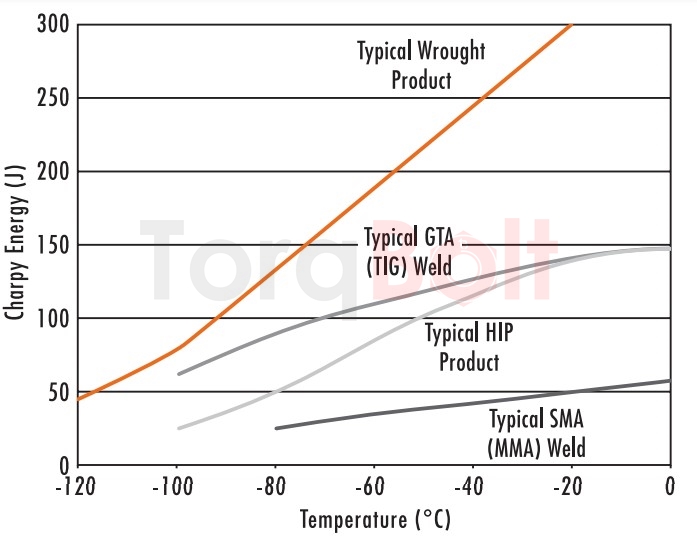

Zeron 100 has good impact strength. There is no true ductile brittle transition, just a gradual decrease in impact energy as the temperature is lowered. The impact energy varies according to product type and production route. Some typical values are shown in Figure 1 on the following page.

The impact strength of welded Zeron 100 is slightly less than that of parent metal (See also figure 1). Present data suggests that 30 ft. lbf (40J) is a suitable acceptance criterion for duplex stainless steels and Figure 1 shows that 40J is achievable with all product forms of Zeron 100 down to very low temperatures.

However, to obtain good impact toughness after welding, a higher level of impact toughness is required in the parent metal. Zeron 100 typically has a Charpy toughness > 70J at -58°F (-50°C).

Figure 1 - Typical Charpy Impact toughness transition curves

Surface Treatments

- Xylan 1070 / 1014 / 1400 / 1424

- Xylar 2 / 101

- SermaGard 1105 / 1280

- Dacromet 320 / 500

- TakeCoat 1000 Ceramic

- Magnigard

- MolyKote

Certifications

- ISO 9001 - 2015 Certified

- PED 2014/68/EC

- NACE MR0175/ISO 15156-2

- NORSOK M-650 MDS 055

- DFAR

- MERKBLATT AD 2000 W2/W7/W10